Typically you simply must make your individual rigging instruments when time is brief. I had a fishing journey arising in a pair days however had misplaced my PR Knot Bobbin that I used to rig up my wind-on leaders. So as a substitute of being out of luck, I made a decision to make my very own Wind-On Chief Serving Bobbin utilizing some PVC fittings and different elements I bought on the native ironmongery store. To make this DIY Wind-On Chief Serving Bobbin you’ll solely want one energy instrument, a cordless drill, and a few drill bits.

DIY Articles on OutdoorHub

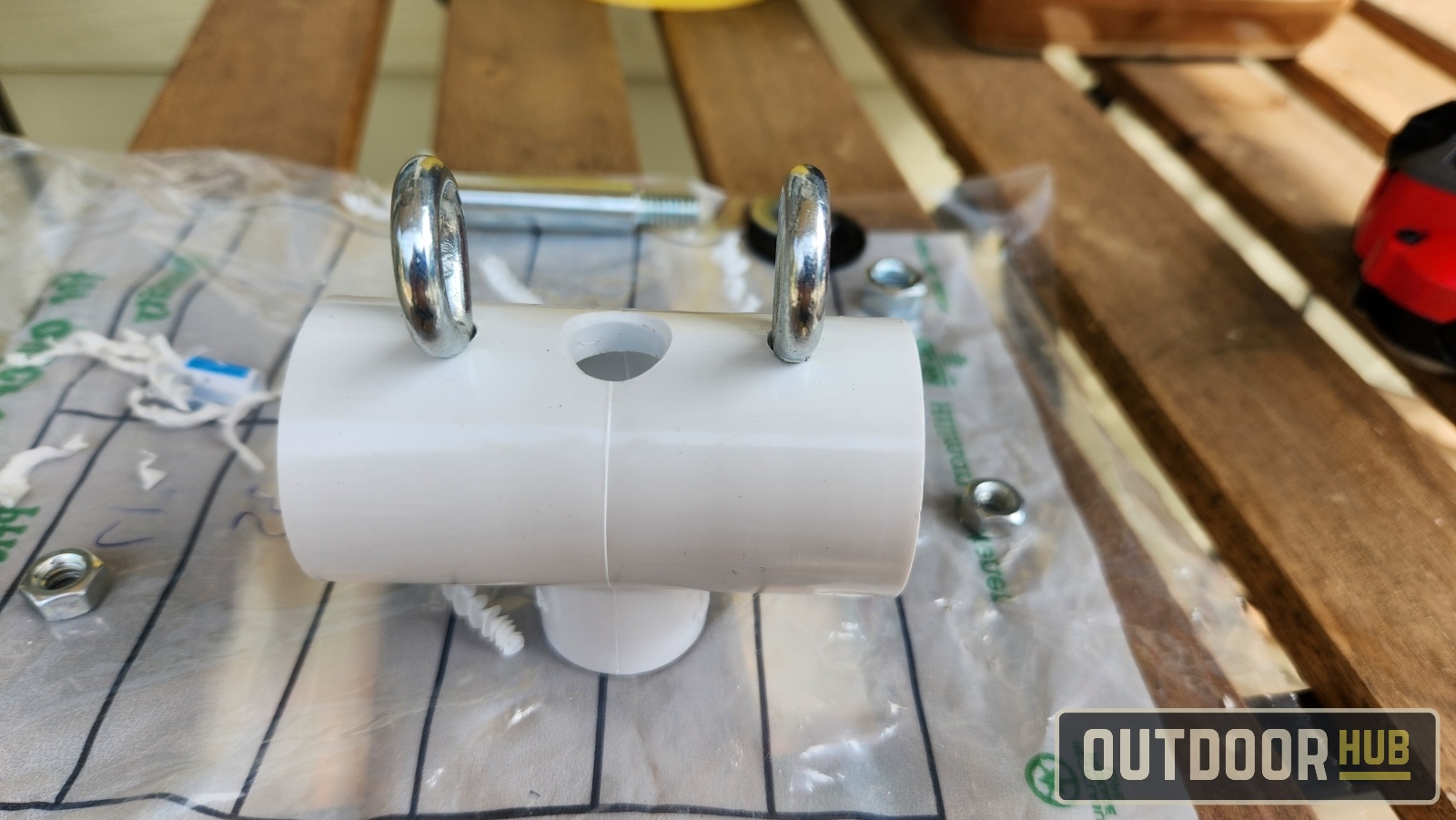

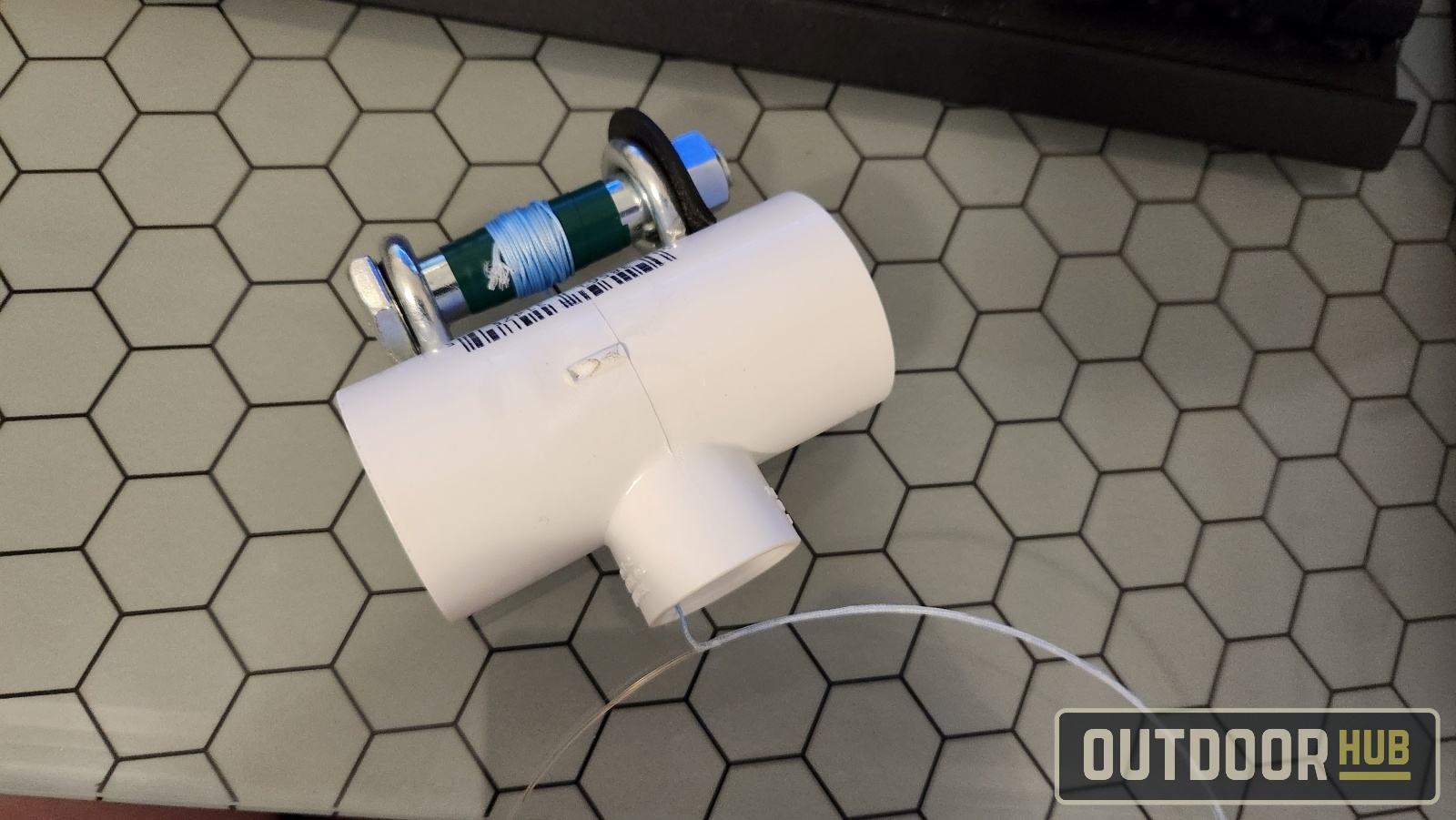

To make this, I purchased 1- 1″to 1/4″ decreasing T, 2 – threaded eye bolts, 1 – axle bolt and nut, 1 – washer, 1 – rubber washer, and, 2 rubber o-rings. You possibly can in all probability simply use a 1/4″ T PVC becoming as a substitute of a decreasing one however I used on that the attention bolts and axle bolt it on. In case your ironmongery store has different bolt choices go for the smaller PVC becoming.

Step one is to drill a small pilot gap in the midst of the “T” PVC becoming. You wish to steadily work your manner up with drill bits in dimension so the PVC doesn’t seize the drill bit and harm you. However in case you have a vice or drill press, you possibly can skip this step for those who can lock down the T piece. In the event you do have these instruments you possibly can simply begin with the most important drill bit with no worries. After you end drilling make sure that to deburr the outlet.

The subsequent step is to drill the holes for the 2 eye bolts into the PVC pipe becoming. I simply arrange eye bolts on the axle bolt as it will be for it’s remaining configuration to determine the place to drill on the PVC pipe. Then I simply drilled two small holes simply large enough for the attention bolts.

Take aside the attention bolt – axle bolt arrange and place the attention bolts into the holes you drilled. Use the offered nuts and lock the attention bolts into place.

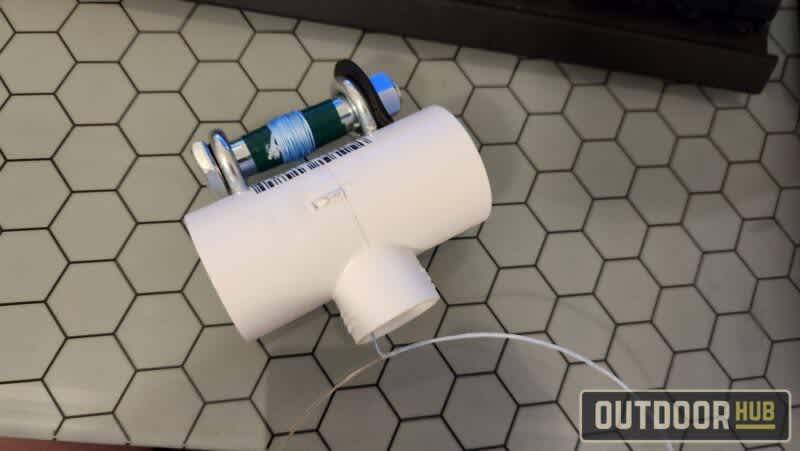

Subsequent seize the attention bolt and put one of many o-rings onto it, sliding the o-ring all the best way as much as the pinnacle of the axle bolt.

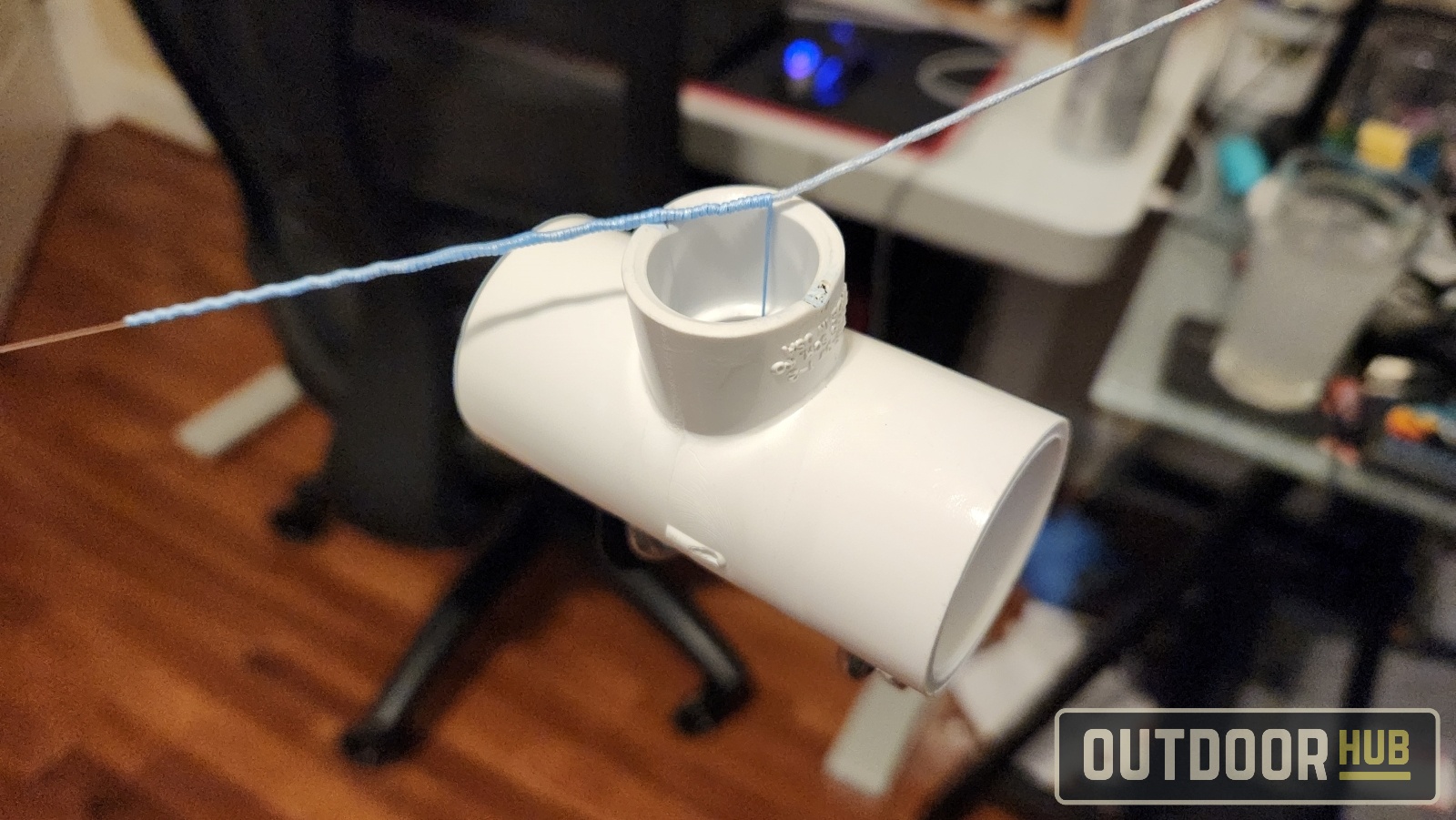

Then slide the axle bolt into the eye-bolts on the PVC becoming. Then put the rubber washer and metallic washer on the bolt. High them off by threading on the nut behind the washers. The washer and o-ring act as a supply of friction so that you can modify the stress on this wind-on chief serving bobbin.

Subsequent, you wish to notch the 1/4″ aspect of the PVC becoming, I used a heated nail and a small drill bit to make the notch. Then a sanding pad to spherical off any sharp or arduous edges, you wish to make sure that something that would presumably injury your line is taken care of. The aim of the notch is to cradle your chief as you end serving any leaders you are attempting, that manner the bobbin stays in place extra simply.

The ultimate step to complete off the bobbin is to throw a bit {of electrical} tape onto the axle bolt. That manner your braided mainline doesn’t slip when you’re placing pressure as you might be serving a frontrunner.

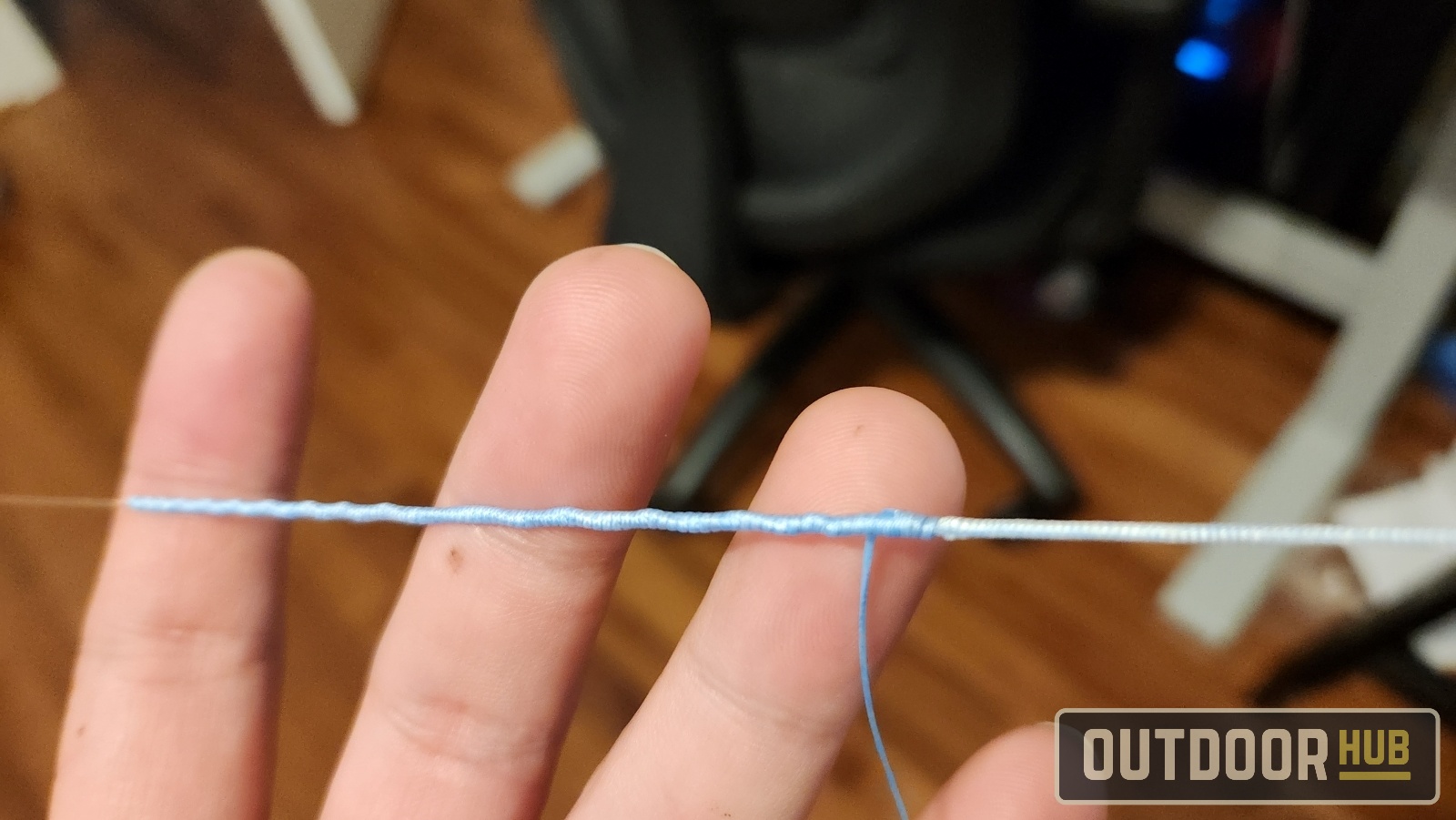

Right here I’m utilizing my DIY Wind-On chief serving bobbin to tie up a serving knot to complete the connection between my 80lb hollow-core braid and a 60lb monofilament prime shot on considered one of my trolling rods. By utilizing the stress offered by the rubber washer I’m able to make two layers of tight wraps of line across the chief to lock the road into place. After which a reverse Uni knot locks the loops down making for a 100% knot energy connection that may simply run by way of the guides of any rod. So in case you have a visit arising within the subsequent few days and don’t have the time to order a bobbin, take into account making your individual. This takes a minimal quantity of effort and price me lower than $15 to make and took lower than an hour to assemble. It doesn’t work in addition to a purpose-made industrial Wind-On Chief Serving Bobbin nevertheless it does positively work in a pinch making serving knots.